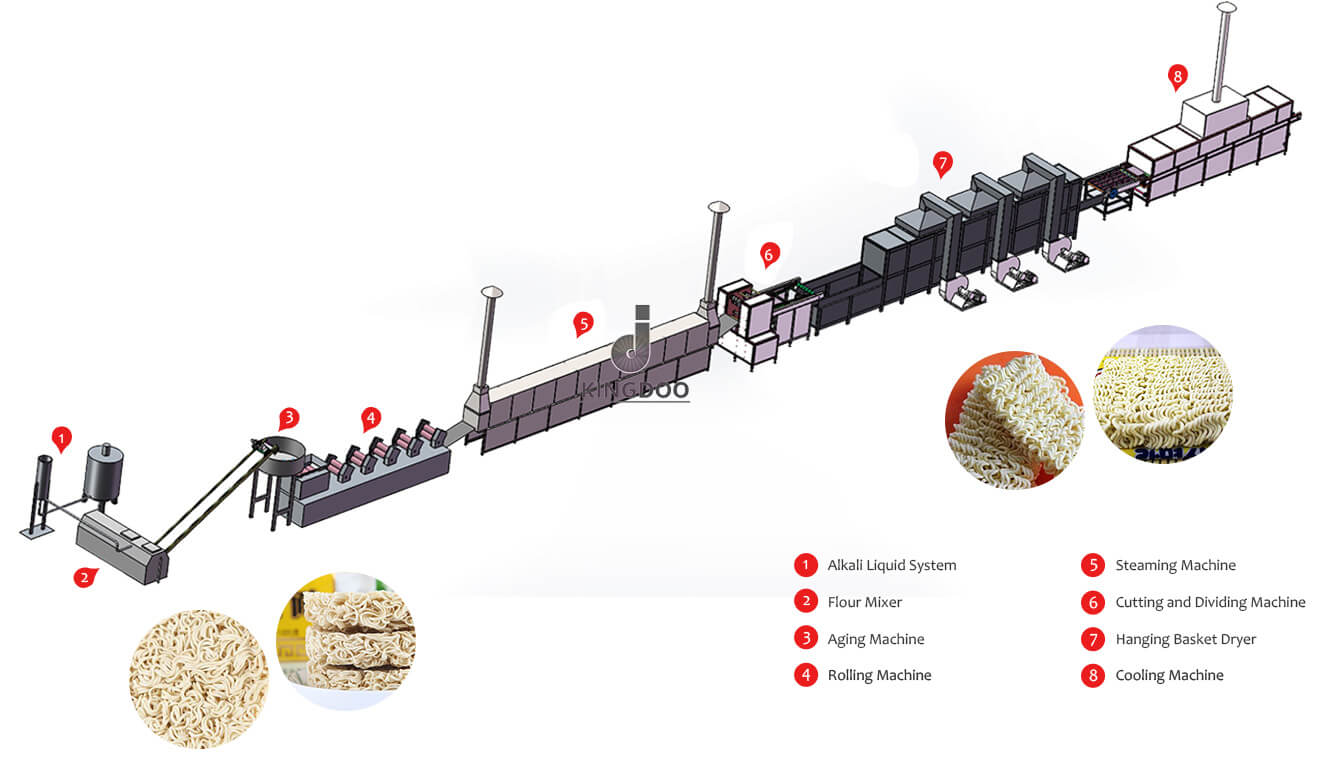

Non-fried instant noodle making machine

Process flow: Salt water mixer and measurement-----mixing-----dough aging------pressing----- steaming-----cutting and dividing------ drying------ cooling------convey- ----packing

Dried noodle making machine also called non-fried noodle making machine,it’s different with fried instant noodle machine. Fried noodle cake need through oil frying.Dried noodle cake don’t need it.

Our factory non-fried noodle making machine has model KDN200 ,KDN300,KDN400,KDN510,KDN630,KDN800,KDN 1000.

drying time is about 45 minutes. But sometimes it's 30-40 minutes if customer's noodle cake is thin.

We can also choose different kinds of dryer accrod customer's workshop size . For example we can make 3 layers, 5 layers ,7 layers, 9 layers drying machine . The length will be short and he height will change tall if dryer has more layers . This is flexible.

We have a big advantage for the non-fried noodle making machine. Before we made one set model 1000(means noodle machine roller width is 1 meter) dried noodle machine for my customer. The capacity is 300,000 pics 8 hours. This is a large capacity.

| Sequence | Product Image | Product Name | Product Description |

1 |

|

Alkali liquid system |

Water mixed with additive such as salt, alkali. body,shaft,mixing device stainless steel304,water measuring automatically |

2 |

|

Flour mixer | Flour and water combined and mixed full,mixing tank made of stainless steel 304,mixing shaft,water injection pipe,safety head,cover made of stainless steel,supporter,driving shaft,driving fitting,fastener made of carbon steel |

3 |

|

Aging Machine |

Second time aging for dough sheet,mixing tank made of stainless steel 304,mixing shaft,water injection pipe,safety head,cover made of stainless steel. supporter,driving shaft,driving fitting,fastener made of carbon steel |

4 |

|

Rolling Machine |

Press flour into dough sheet,feeder,roller protective plate,guard board on two sides made of stainless steel.roller side,supporter,driving fitting made of carbon steel. scrapper: copper ,guard board for roller:nylon noodle press roller: solid alloy ,dough sheet conveying belt: food grade |

5 |

|

Steaming Machine |

steaming groove,cover,spray pipe,conveying chain,net belt,orbit,exhaust pipe,exhaust cover, net belt washing tank made of stainless steel304. supporter:made of stainless steel |

6 |

|

Cutting and Dividing machine |

Cutting, folding, dividing, forming the dough pieces and entering boxes, it can form square or circular dough pieces from different molds. made of stainless steel,dividing plate:silica gel, include centralized oil supply device |

7 |

|

Hanging Basket Dryer |

Supporter,chain wheel,chain,gear made of carbon steel, Inner and outer side guard plate made of sus ,Circular conveying chain:40 Mn C2062 x 4L carbon steel Noodle trays made of sus304 , thickness is 1.2mm , Heat insulating material: rock wool |

8 |

|

Cooling Machine |

Lower the temperature of dough pieces to meet the demand of packing,conveying net belt made of stainless steel 304. conveying chain: made of carbon steel,outer guard plate made of stainless steel |

|

Model |

Power |

Steam Consume |

Area(m) |

Worker |

|

30,000bags/8h |

42KW |

1000-1200KG/H |

L40*W5*H4 |

4 |

|

60,000bags/8h |

56KW |

1000-1200KG/H |

L55*W5*H4 |

4 |

|

80,000bags/8h |

68KW |

1300-1500KG/H |

L68*W6*H4 |

5 |

|

120,000bags/8h |

83KW |

1800-2000KG/H |

L80*W6*H4 |

5 |

|

160,000bags/8h |

106KW |

2200-2400KG/H |

L85*W7*H4.5 |

5 |

|

200,000bags/8h |

114kw |

2400-2700KG/H |

L90*W8*H4.5 |

6 |

|

230,000bags/8h |

125kw |

2600-2800KG/H |

L100*W8*H4.5 |

6 |

Please feel free to submit your inquiry information to us! our sales manager will contact with you as soon as possible.