Instant cup noodle making machine

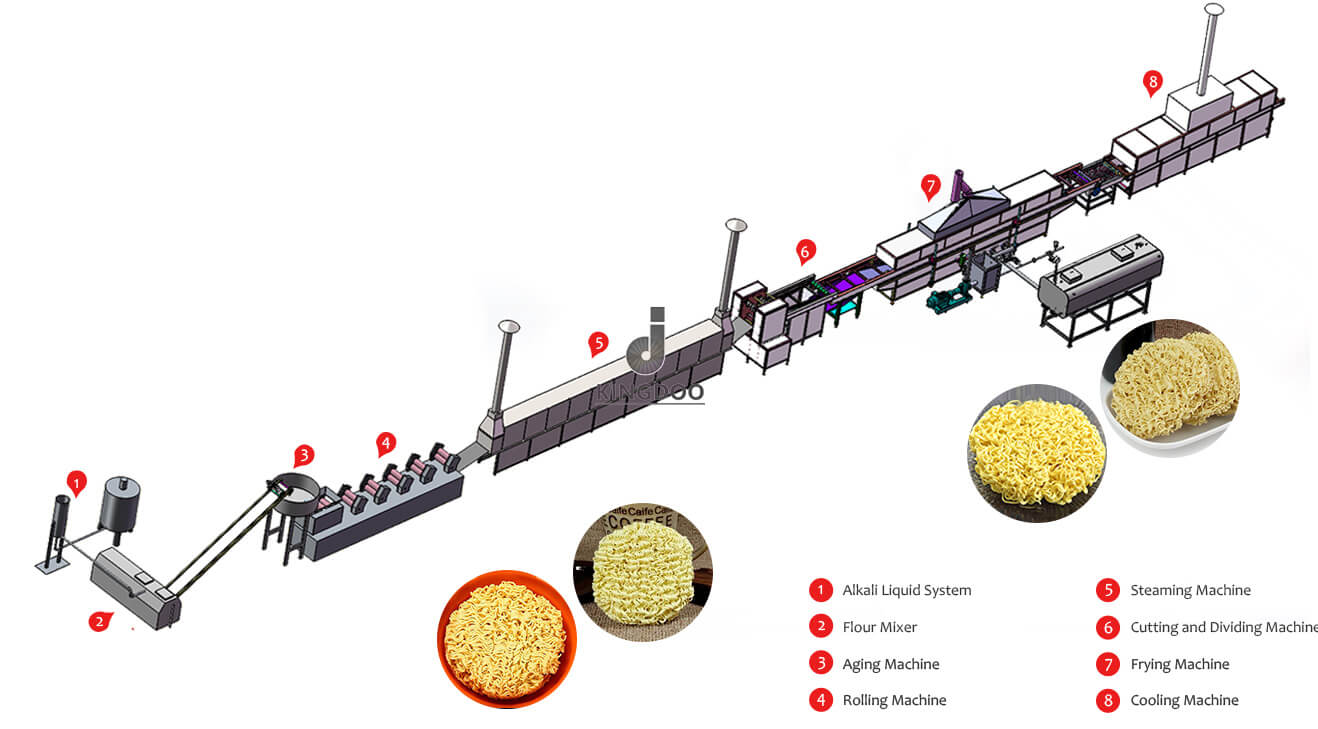

The fried instant cup noodle processing line include ,Alkali water mixing and measuring---flour mixing---dough aging---rolling---steaming---cutting and dividing ---frying---cooling---conveying---packing

Cup is usually made of paper or PE , has double or single paper . Customer can choose to buy cup making machine or buy cups directly from the market.

There are also one fork and seasoning bag matching with noodle cake .It's easy for people eating when they are outside.

What's the difference between the instant cup noodle making machine and square square noodle making machine?

The front parts are all same like flour mixing machine, rolling machine ,steaming machine. There are two parts are different.First part is noodle cutting and folding machine.

Square noodle cutting and folding is different with round noodle cutting. They have a different working way.

Second part different is mold (noodle box), one is square shape box, one is round noodle box.

Now with our factory technology development , The instant cup noodle making machine can produce both cup shape and sqaure shape noodle cake. Customer only need buy one more square noodle cutting machine and one set noodle box with noodle box exchanging machine.

| Sequence | Product Image | Product Name | Product Description |

1 |

|

Alkali liquid system |

Water mixed with additive such as salt, alkali. body,shaft,mixing device stainless steel304,water measuring automatically |

2 |

|

Flour mixer |

Flour and water combined and mixed full,mixing tank made of stainless steel 304,mixing shaft,water injection pipe,safety head,cover made of stainless steel. supporter,driving shaft,driving fitting,fastener made of carbon steel |

3 |

|

Aging machine |

Dough aging, improve the elasticity of the flour. tray,rod made of stainless steel 304 driving fitting,supporter made of carbon steel |

4 |

|

Rolling machine |

feeder,cover made of stainless steel.roller side,supporter,driving fitting made of carbon steel. scrapper: copper ,guard board for roller:nylon ,noodle press roller: solid alloy ,dough sheet conveying belt: food grade |

5 |

|

Steaming machine |

To make slitted and waved noodle mushy and shaped. steaming groove,cover,spray pipe,conveying chain,net belt,orbit,exhaust pipe,exhaust cover, net belt washing tank made of stainless steel304. supporter:made of stainless steel |

6 |

|

Cutting and Dividing machine |

Cutting, folding, dividing, forming the dough pieces and entering boxes, it can form square or circular dough pieces from different molds. made of stainless steel,dividing plate:silica gel,include centralized oil supply device |

7 |

|

Frying machine |

Dehydrated by frying, fixing the shape of dough pieces, making dough crispy to taste good. heating system,temp control automatically,oil pot up and down by manual and automatically . oil pot:carbon steel,the cover of oil pot:stainless steel,chain and orbit :carbon steel |

8 |

|

Cooling machine |

Lower the temperature of dough pieces to meet the demand of packing,conveying net belt made of stainless steel 304. conveying chain: made of carbon steel,outer guard plate made of stainless steel |

| Model | Power | Steam consumption | Workshop dimension(m)(Single layer steamer) | Workshop dimension(m)(multi-layer steamer) | Workers |

| 30000pics/8h | 42kw | 1000-1200KG/H | 50*5*4 | 40*5*4 | 4 |

| 60000pics/8h | 56kw | 1200-1400KG/H | 55*5*5 | 45*5*4 | 4 |

| 80000pics/8h | 68kw | 1300-1500KG/H | 65*6*4 | 55*6*4 | 5 |

| 120000pics/8h | 83kw | 1800-2000KG/H | 75*6*4 | 65*6*4 | 5 |

| 160000pics/8h | 106kw | 2000-2200KG/H | 85*7*4.5 | 75*7*4.5 | 5 |

| 200000pics/8h | 114kw | 2400-2600KG/H | 90*8*4.5 | 80*8*4.5 | 6 |

| 230000pics/8h | 125kw | 2600-2800KG/H | 100*8*4.5 | 90*8*4.5 | 6 |

Please feel free to submit your inquiry information to us! our sales manager will contact with you as soon as possible.